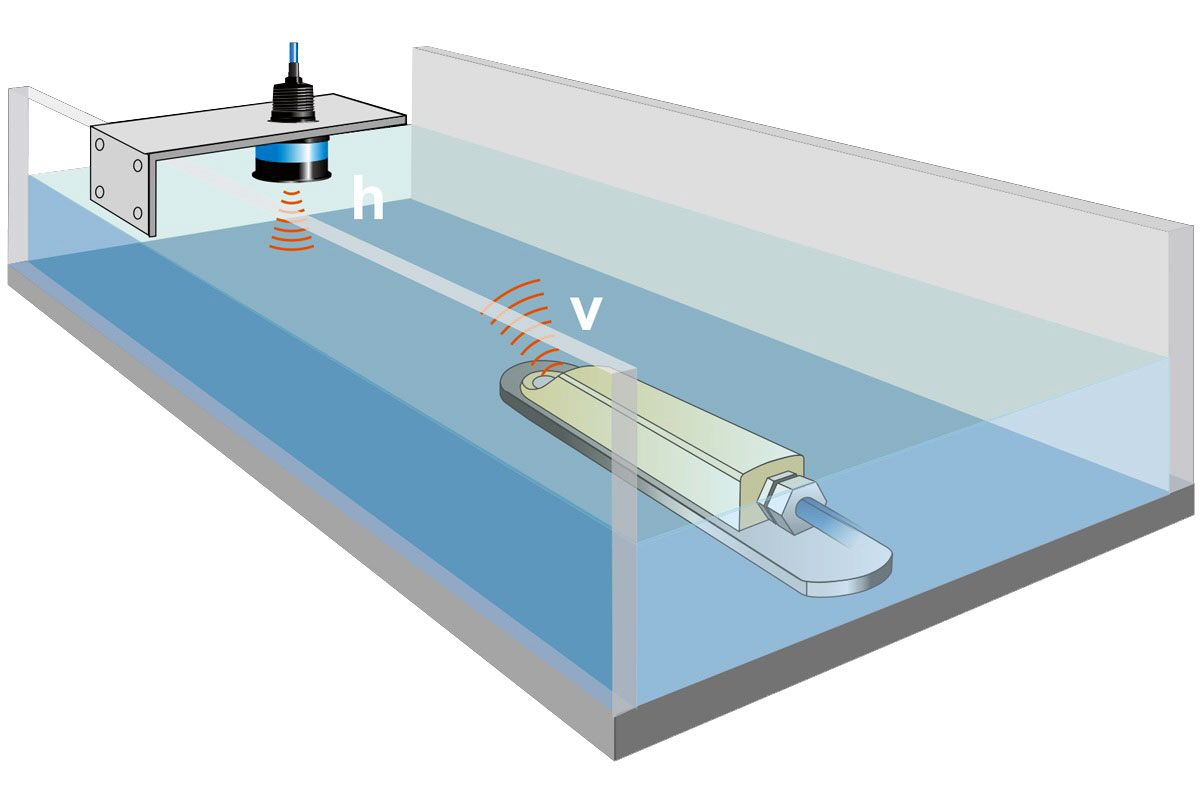

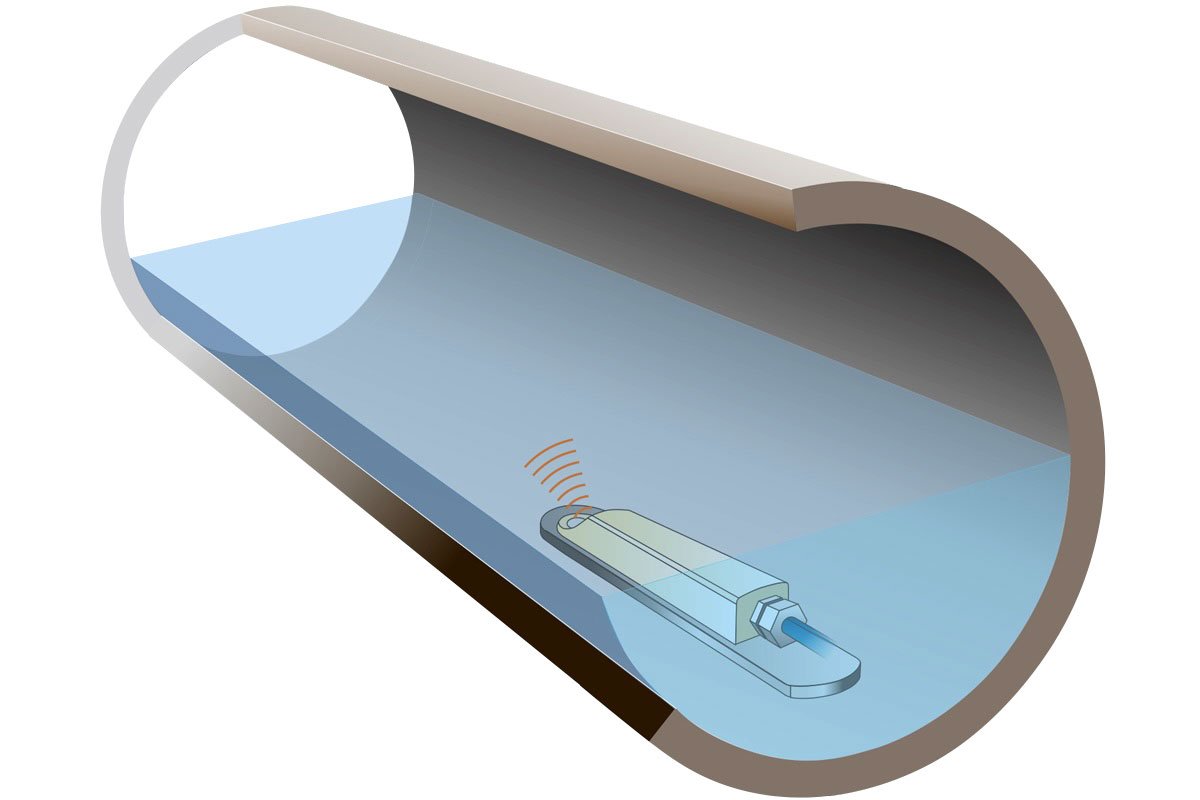

Thanks to ultrasonic cross-correlation technology with flow profile detection, the NivuFlow 750 offers an extremely accurate flow measurement system for slightly to heavily polluted media, in partially filled or full channels and pipes, even under difficult hydraulic conditions.

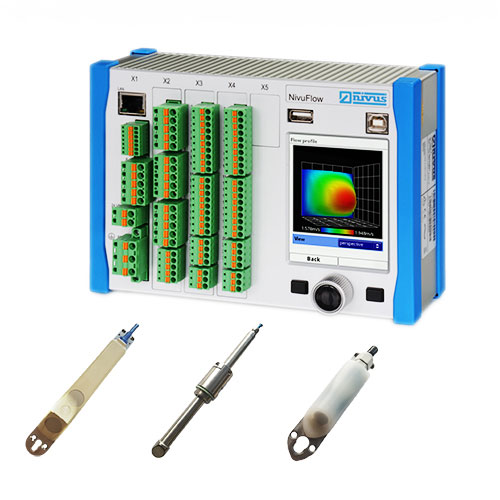

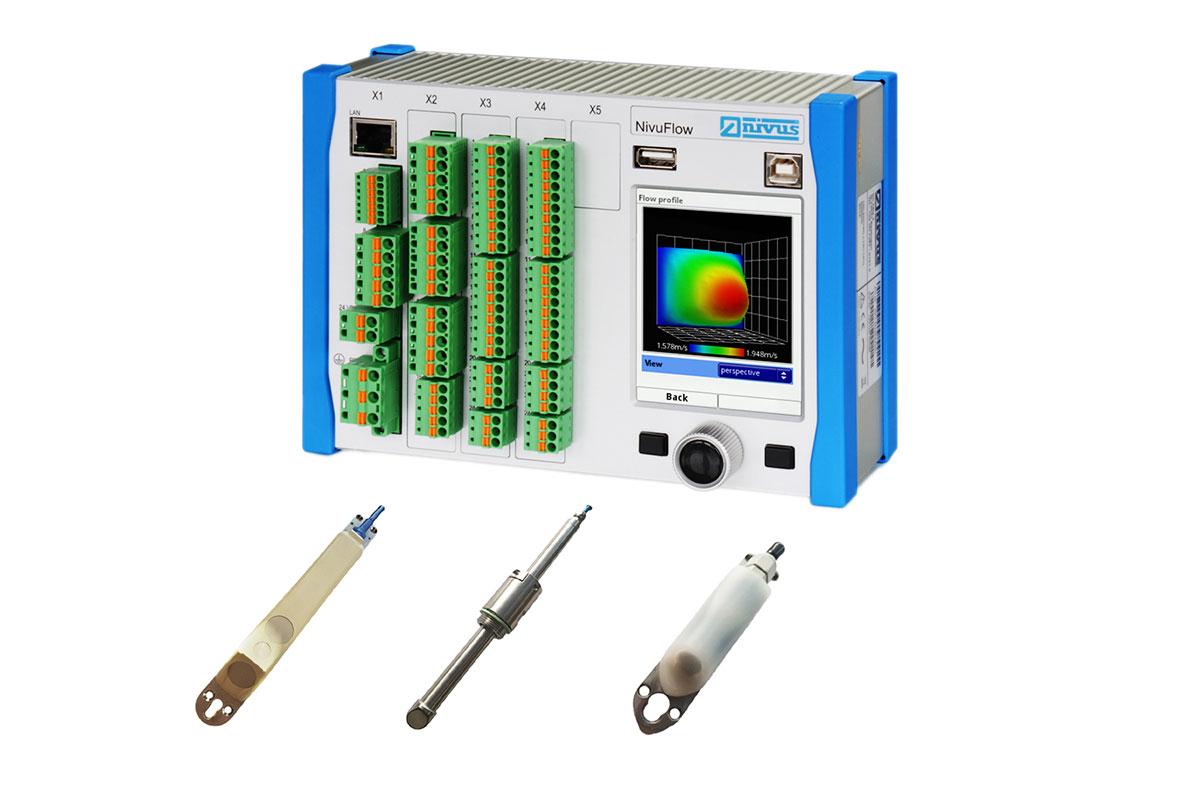

The NivuFlow 750 can manage up to 3 measurement points and 9 sensors in parallel.

It can be operated as a stand-alone unit, even featuring a built-in datalogger and telemetry option, or coupled to a third-party control system (PLC, SCADA, etc.).

On-site set-up is simple, fast and extremely user-friendly, thanks to its color display and intuitive one-handed operation.

The NivuFlow 750 is also available as a battery-powered stand-alone version (see NivuFlow Mobile 750).

Scroll down for additional pictures.

Applications

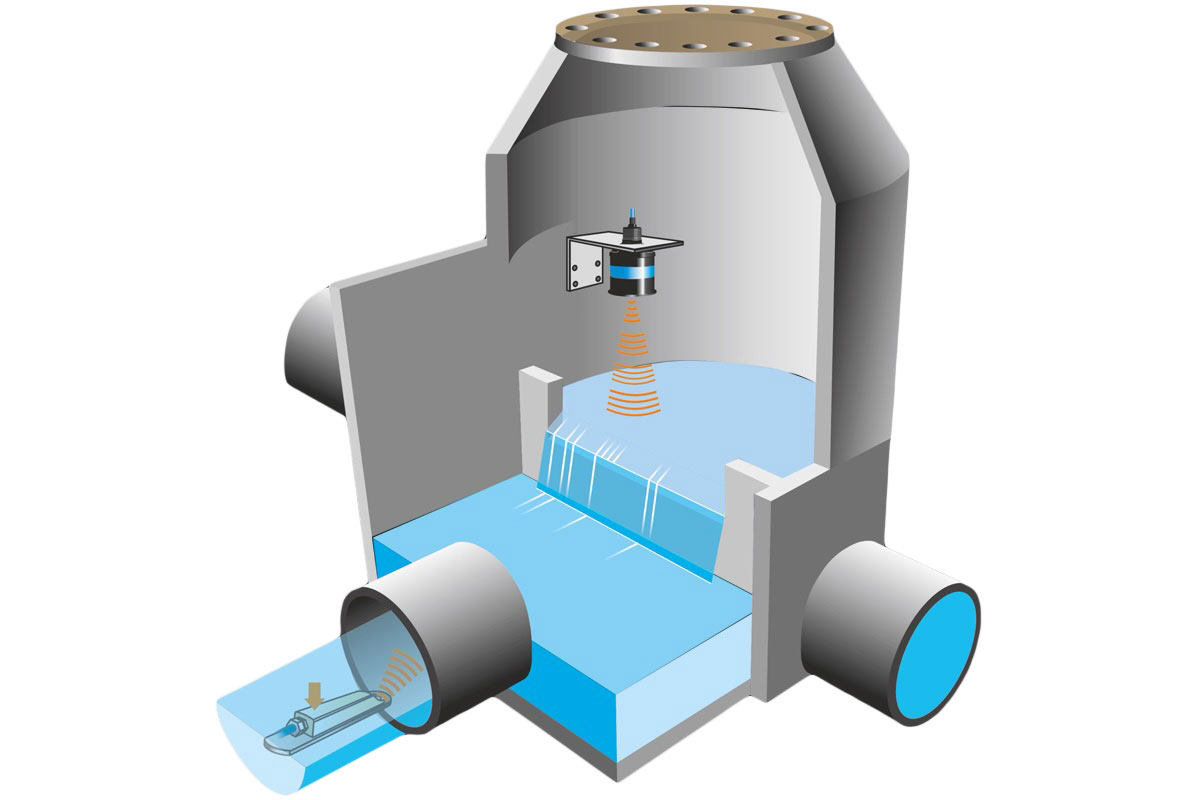

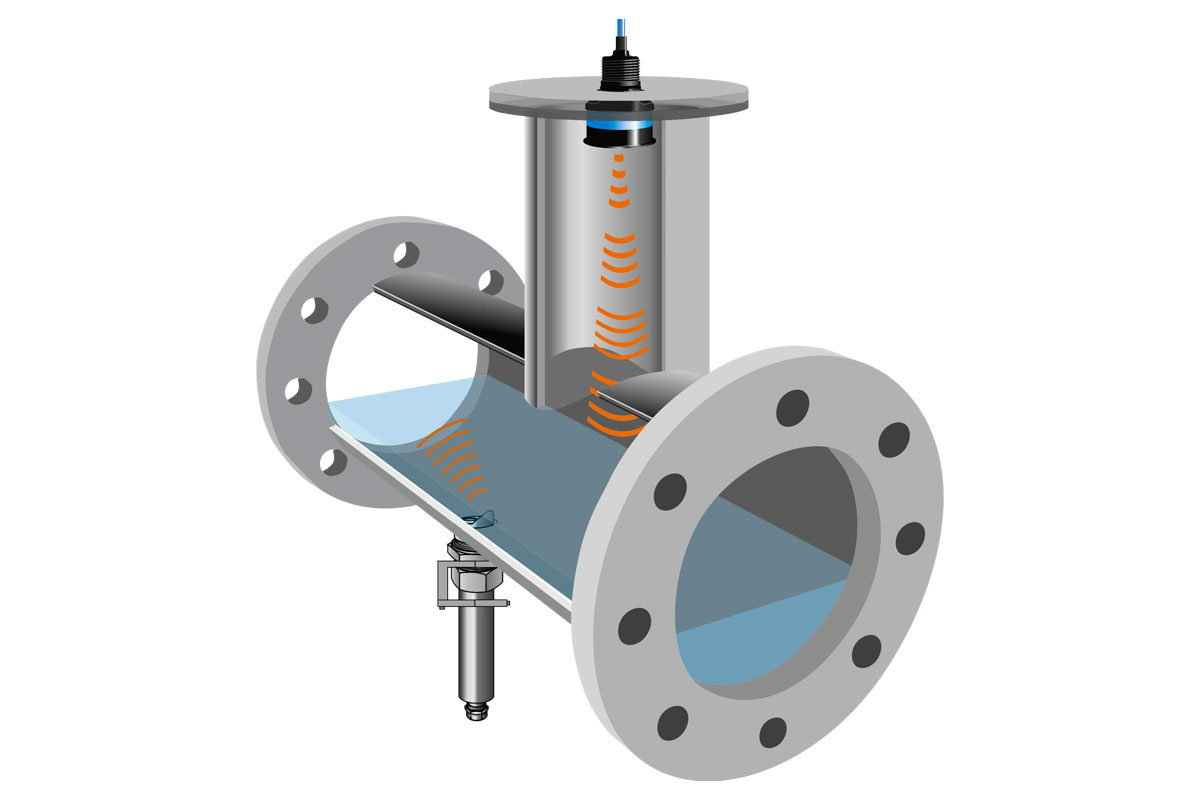

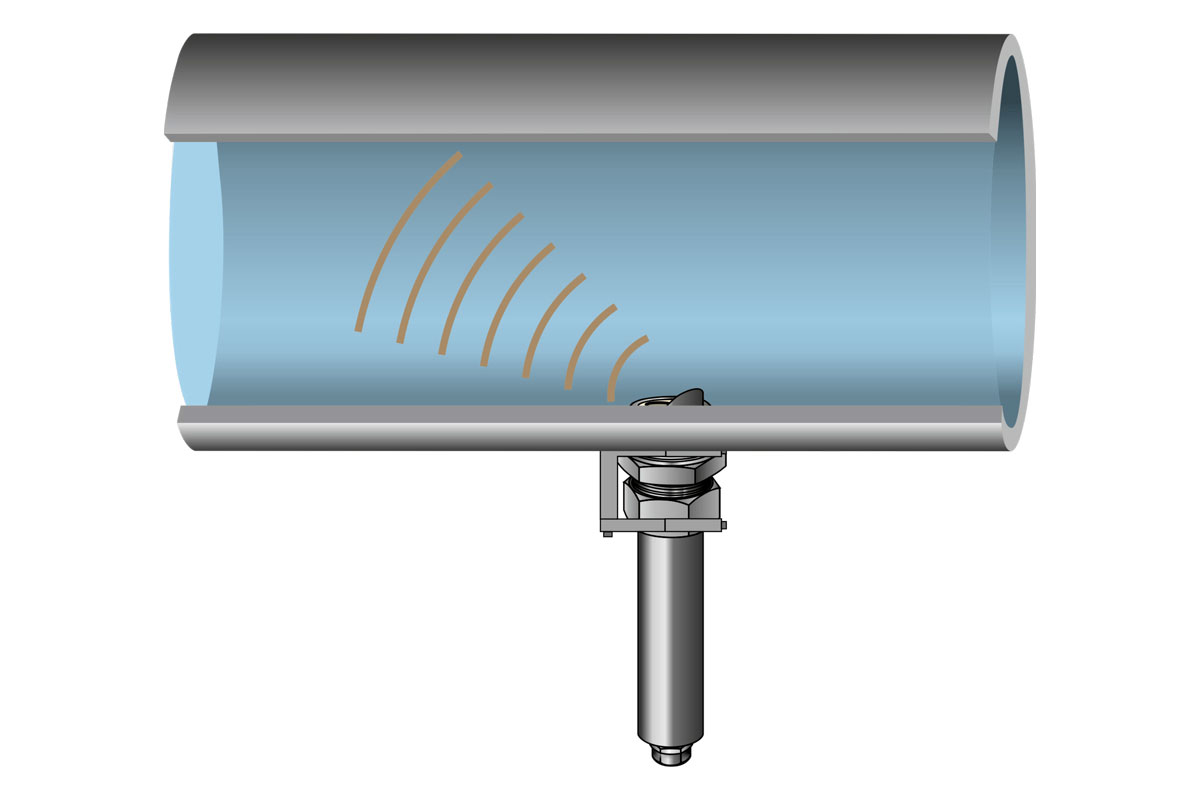

- Slightly to heavily charged fluids in open channels or full or partially filled pipes

- Sewerage systems, pumping stations

- Wastewater treatment plants: inlet, outlet, aeration tank outlet, sludge recirculation, sludge treatment, fermentation outlet, flocculant dosing

- Diagnosis, infiltration or capacity studies

- Control of discharges, parasitic waters, search for leakage flows

- Sewage Overflow monitoring

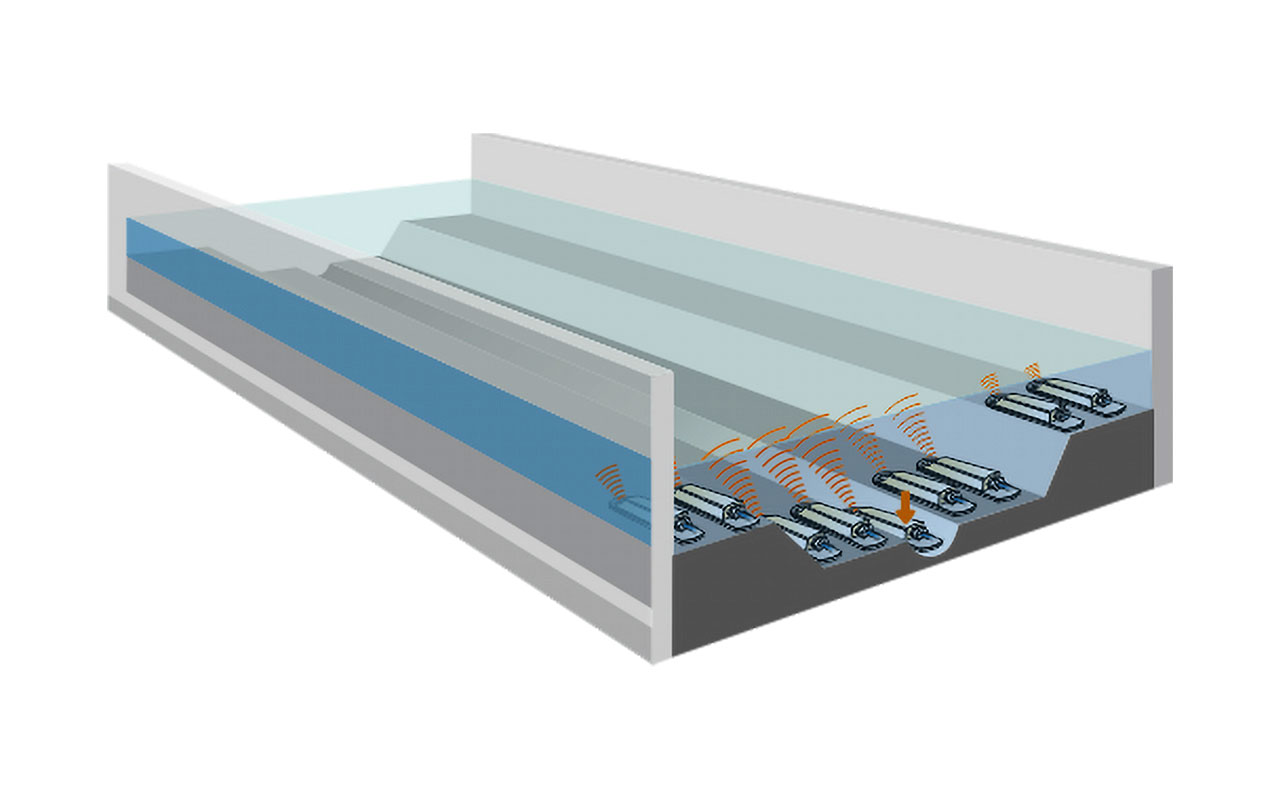

- Stationary measures in rainfall retention structures such as stormwater, retention or pollution control basins

- Industrial water networks

- Metering for billing purposes

- Drainage pipes

- Recycling sludge lines

Main benefits

- High-accuracy measurement thanks to cross-correlation velocity profiling technology, with no need for calibration, even under changing and difficult hydraulic conditions (see KNOWLEDGE section)

- 3D visualization of flow profiles in real time

- Flexible range of velocity sensors (see Velocity Profiling Sensors) and level sensors (integrated with velocity sensors or external, hydrostatic, ultrasonic, radar)

- Multi-sensor capability for large-diameter pipes or wide channels, or for system redundancy (up to 9 velocity sensors)

- Up to 3 measurement points can be managed by the same converter-transmitter

- Sensors can be installed without stopping the flow, without intervention in the environment, and without additional mounting equipment such as string rings or mounting plates (cylindrical insertion sensors).

- Direct, simple, fast and user-friendly configuration and commissioning, with no need for additional software (integrated display and rotary navigation knob).

- Diagnosis, analysis and simulation functions integrated into the converter-transmitter (no need for additional software)

- Control function also available (flow control in stormwater retention basins, sewers with storage and overflow capacity, etc.)

- Can be used as a stand-alone system, with integrated datalogger and telemetry option, or coupled with a third-party control system (PLC, SCADA, etc.) thanks to the various available connectivities (4-20mA, relay, Modbus, Hart).

- Approval for potentially explosive areas Class I/Division 1 (optional)

Specifications

VELOCITY AND LEVEL SENSORS

- Bidirectional Velocity measurement using ultrasonic cross-correlation technology; see details in Velocity Profiling Sensors)

- Level Measurement by sensor integrated in the velocity sensor or external (ultrasonic, radar or hydrostatic); see Sensors section (consult us for third-party sensor validation)

- Measurement Accuracy

— Velocity: < 0.5 % +5mm/s (v<1m/s), < 1 % (v>1m/s)

— Level: depending on sensor

— Flow rate: depending on operating conditions (consult us for case studies)

POWER SUPPLY

- Supply voltage:

— 100 to 240 V AC, 47 to 63 Hz

— 9 to 36 V DC - Power Consumption: 14 VA typical

- Can be powered by solar panel for isolated sites (or stand-alone battery-powered solution; see NivuFlow Mobile 750)

ENCLOSURE - ENVIRONMENT

- Material: Aluminum, PVC (converter)

- PVC field housing available (option)

- Degree of Protection: IP 20 (IP 68 with optional field housing)

- Operating Temperature: -20°C to +70°C (-4°F to 158°F)

- Storage Temperature: -30°C to +75°C (-22°F to 167°F)

- Max. humidity: 80%, non-condensing

OPERATION

- Configuration, Visualization, Diagnostics directly on the converter

- TFT color graphic display: 240 x 320 pixels, 65536 colors

- Graph trends, channel profiles, etc.

- Intuitive one-hand navigation (rotary pushbutton)

- 1.0 GB internal memory, front panel retrieval via USB key

INPUTS-OUTPUTS

- Inputs:

— RS485 digital cross-correlation velocity sensors (up to 9)

— 4-20mA and Hart sensors for level and other measurements (up to 7 depending on model)

— Nivus level sensor

— Digital inputs (up to 10 depending on model) - Outputs:

— 0/4-20mA outputs (up to 4, 12-bit resolution)

— Relay outputs (up to 5)

CONTROLLER FUNCTION

- 3-stage step controller, emergency stop, valve position adjustment in case of malfunction

COMMUNICATION

- Modbus TCP, Modbus Serial RTU, HART®, TCP/IP

- Integrated cellular telemetry (optional)

Related products

- Cross-correlation velocity sensors

- Various installation accessories (consult us)

- NivuFlow Mobile 750

- NivuFlow 7550 (hybrid radar+cross-correlation velocity measurement system)

- PLCs, dataloggers, telemetry systems (see REDY, FLEXY, Multilog...)

- Nivus Web portal